Our Products

Our offering

GrapheneTX presents a comprehensive range of functionalized graphene and CNT, available in diverse particle sizes and forms. Leveraging our eco-friendly production methods, we ensure large-scale manufacturing of these materials. They find their versatility application across various domains, including coatings (like epoxy or urethane), carbon fiber composites, supercapacitors, Li-ion batteries, and engineering plastics (like Nylon-6,6). Our offerings encompass powder, paste, and dispersion options, catering to polar and nonpolar solvents.

Mechanical & Chemical benefits of Functionalized Graphene

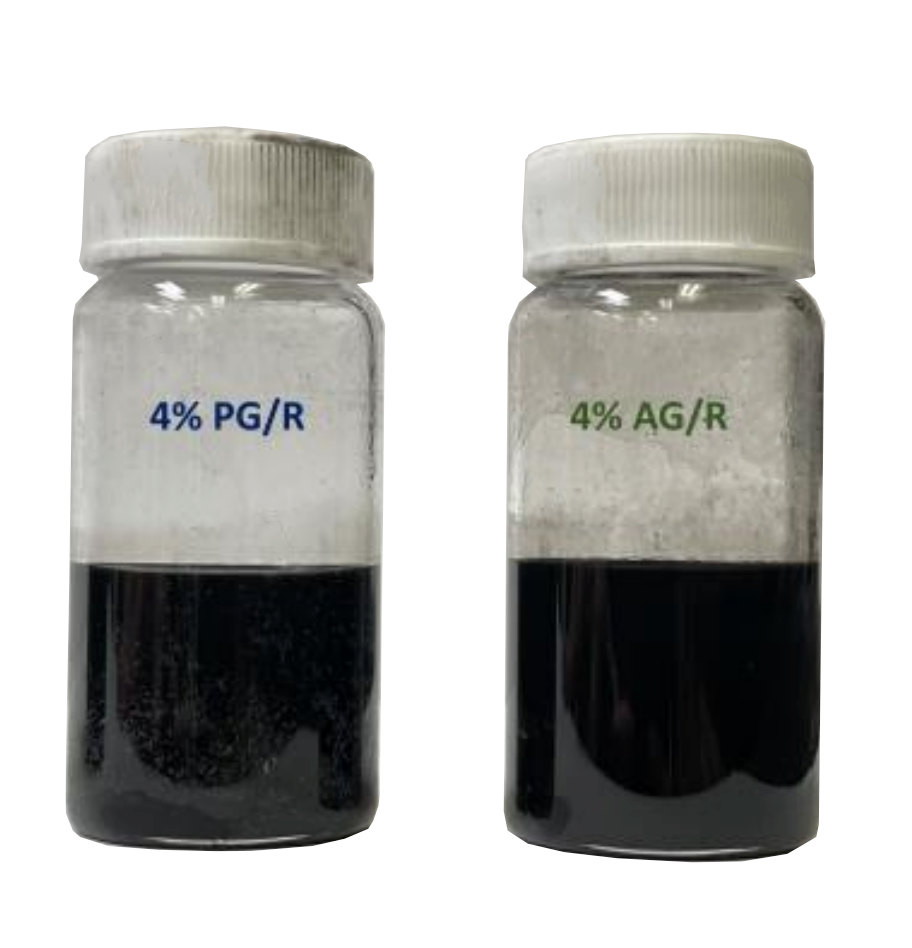

Aminated Graphene (AG) vs Pristine Graphene (PG)

Unlocking the Potential: AG's Superiority Over PG

Discover why AG surpasses PG in every aspect. AG exhibits enhanced chemical versatility, enabling highly customizable and tailored applications. Its advantages include:Easy dispersibility and prolonged dispersion stabilityHeightened mechanical propertiesEnhanced chipping resistanceImproved corrosion resistanceExceptional UV resistance

Graphene structureGraphene sheet

SWNT

Amine (NH20-) Groups in Graphene react with epoxy groups to form strong covalent bondsExcellent fatigue behavior

Results of 1,000,000 cycle bending test with 0.02% Aminated graphene filled glass fiber composite vs control sample.

Fatigue life improvement by AG use at different # of bending cyclesFatigue Behavior of AG - GF Composites: 1 million bendings (Stress ratio = 0.1)Enhanced Storage Stability: Aminated Graphene’s Advantage

Dispersions containing aminated graphene in compatible solvents demonstrate superior stability compared to pristine graphene dispersions. Aminated graphene exhibits prolonged dispersion stability, as depicted in the image, where aminated graphene maintains its stability for 120 days in epoxy hardener, surpassing the performance of pristine graphene. Enjoy excellent storage life with aminated graphene.

0 day

120 days

Cost and Manufacturing benefits

GrapheneTX's functionalized nano-fillers enhance durability without requiring any changes to the manufacturing process.Adapting the use of nano-fillers does not necessitate additional capital investment.The chemical versatility of our nano-fillers enables easy customizations.Our technology promotes low or even zero waste generation.

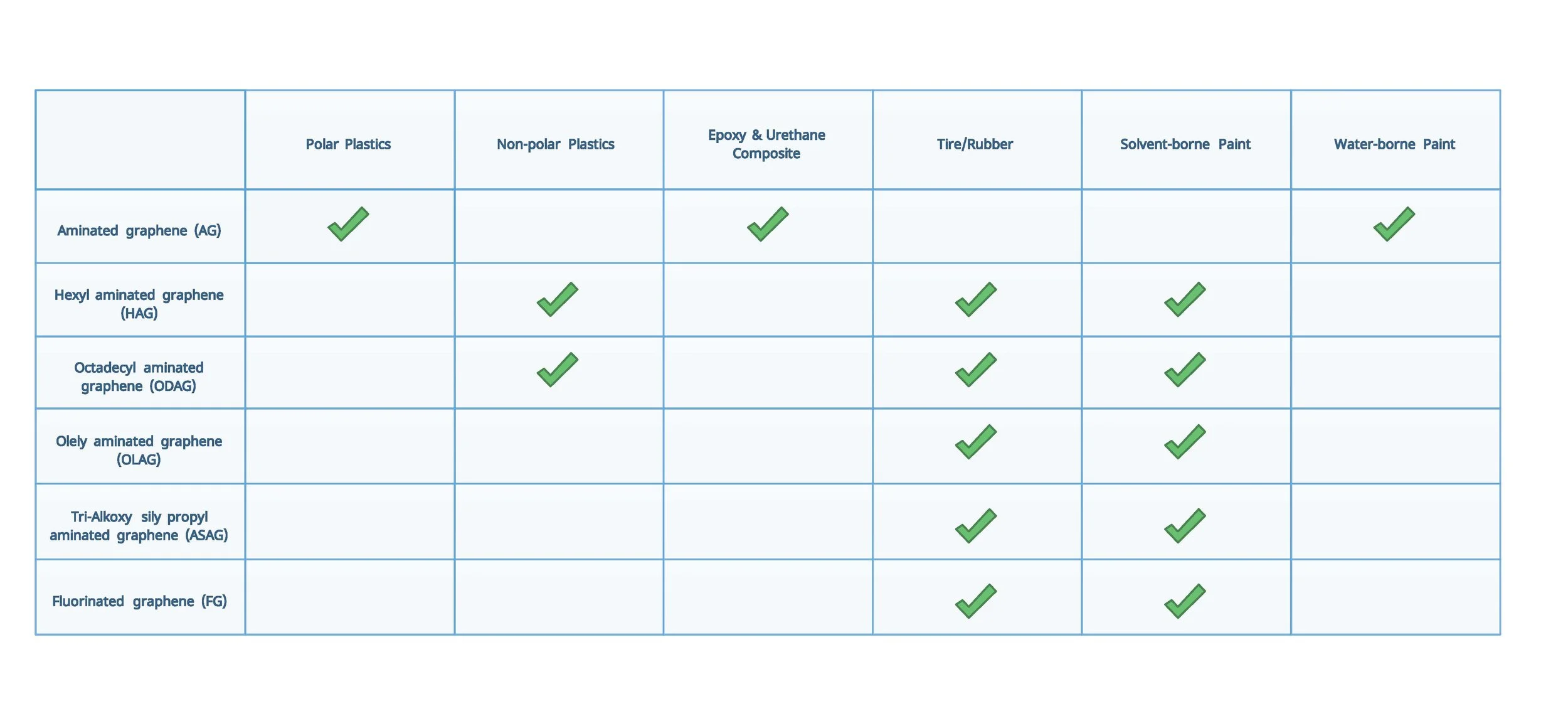

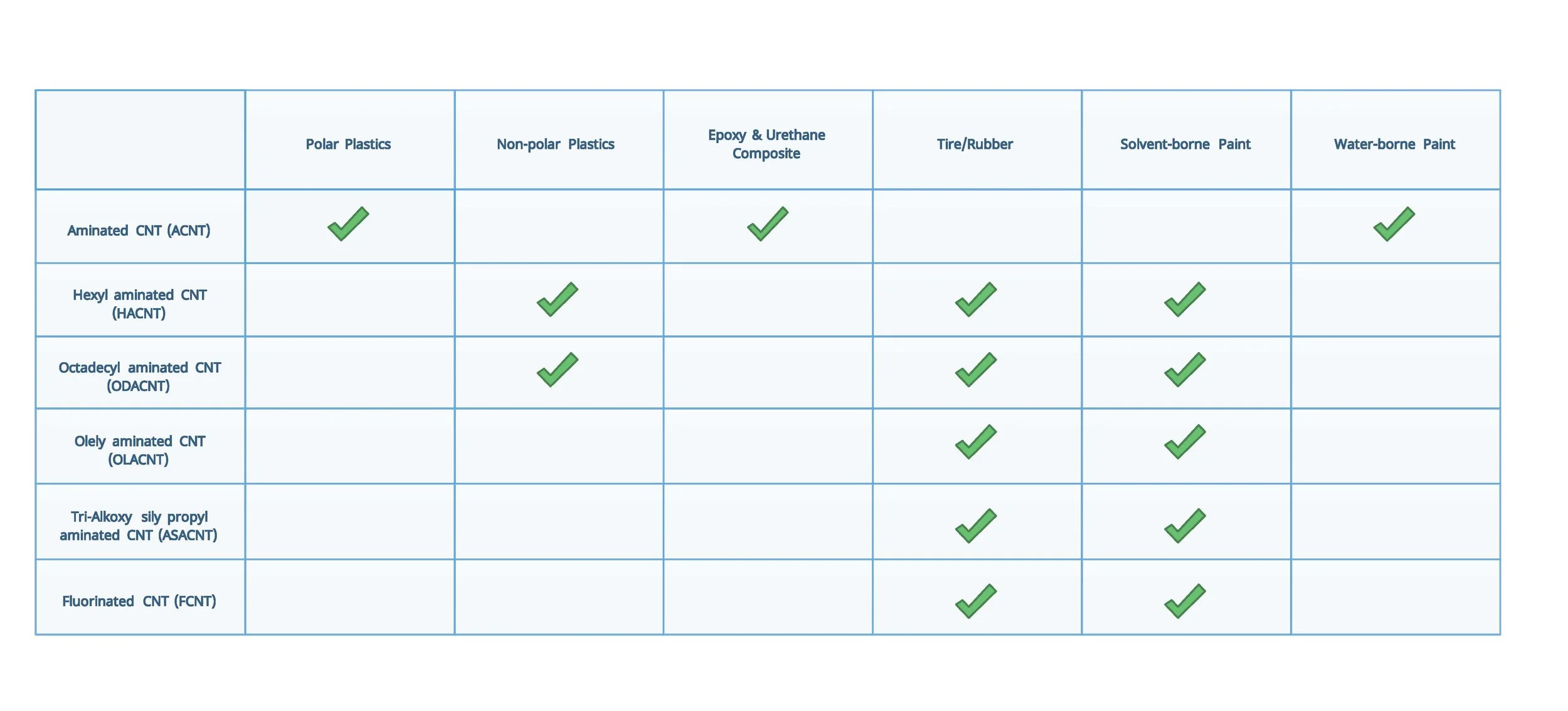

Product Applications

Functionalized Graphene Application

Functionalized CNT Application

Functionalized Graphene & CNT

Powder

Dispersion Solution

Paste

Masterbatch